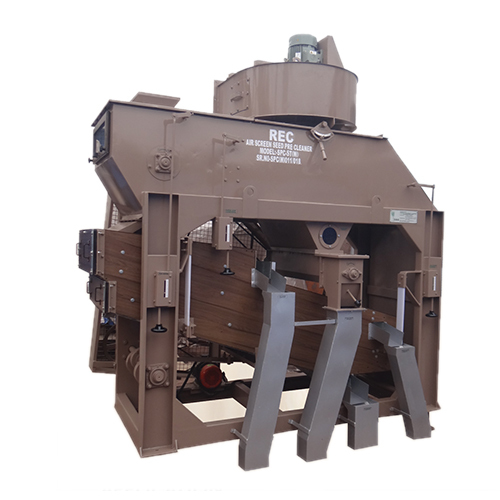

REC Seed Pre Cleaner Model SPC-3T

Product Details:

- Material MS

- Computerized No

- Click to View more

REC Seed Pre Cleaner Model SPC-3T Price And Quantity

- 5 Unit

REC Seed Pre Cleaner Model SPC-3T Product Specifications

- MS

- No

REC Seed Pre Cleaner Model SPC-3T Trade Information

- 50 Unit Per Month

- 10 Days

Product Description

Specification

- Capacity (Based on Wheat): 6.0 Tons Per Hr. at!2% moisture content & 20% Impurities.

- No. of Screens/Layers : 3 Flat, Oscillating (5 Sections)

- Size of each screen

- Top Screen (Scalping) : 1000 x 800 mm (LxW) - In | Section

- Middle Screen : 2000 x 800 mm (LxWx ) - In 2 Sections

- (Close Scalping/Grading) each of 1000 x 800 mm

- Bottom Screen : 2000 x 800 mm (Lx W) - In 2 Sections

- (Sand Removal/Grading) each of 1000 x 800 mm

- Screen Inclination : Fixed

- Screen Oscillation Fixed/Variable

- Screen Cleaning System

- Top Screen : Rubber Ball System

- Middle Screen : Rubber Ball System

- Bottom Screen : Rubber Ball System

- Total Screen Area > 4.0 Sq. Mtr.

- Total Length of Seed

- Travel on Screens : 5.0 Meters

- No. of Air Aspiration : 2 (Double Stage - Pre & Post)

- No. of Reject Augers : (One)

- Fan Capacity > 5100 cfm at 75mm WGSP

- Electric Motor : 5.0 HP & 1.5 HP For Blower & Fr, Sieve Cradle Assembly Respectively

- Overall Size (LxBxH) > 255 x 152 x 275 cms Approx. (With Blower Assembly)

Applicationï

These Seed Cleaners / Grain Cleaners are suitable for the efficient Pre- cleaning of all cereal seeds, oil seeds, foresty seeds, fodder seeds, pulses etc. e.g. wheat, paddy, maize, bajra, urd, moong, gram, soybean, sunflower, mustard, jowar, barley, coffee seeds etc by removing lighter impurities like chaff, husk, dust & dirt/sand and also oversize & under size impurities from the raw seed grain.

Features

- Robust machine with frame of steel & welded structure. All steel construction.

- Feed hopper with suitable feed roller & feed control.

- Dynamically balanced Aspirator Fan (Blower).

- Variable air aspiration with step less Air Control.

- Air Chamber, Screen deck assembly & Spouts are self emptying type.

- High carbon steel strip / UHWM hangers and balanced'eccentrics with connecting rod for screen deck oscillation. ;

- Interchangeable, burrs & curvatures free, easily changeable Screens/Sieves.

- Provision of Bag holders at bagging off height & belt guard.

raw Seed/Grain Is ted into the teed nopper and are evenly distributed by a Tluted teed rolier througn a controlled teed gate on the top Screen. Before falling over the top screen, seeds/grains are subjected to the primary air aspiration that separates lighter impurities like chaff, straw, dust etc. Seeds/Grains are then passed through three screens separations according to width & thickness. After passing through screen separations, cleaned grains / seeds pass through secondary air aspiration where remaining lighter impurities are separated. Final seed/grain and impurities are collected separately through discharge spouts into the bags hooked on the bag holders.

Standard Accessories:

2 meter long Air trunk, One Set of 3 Screens (5 Sections) for one particular Crop Seed & Tool kit.

Optional Accessories Available:

Cyclone Dust Collector, Air Trunk, Surge Bin, Feeding Elevator, Additional Screens.

We also plan, design, manufacture, supply and erect seed processing, grain / spice / pulses cleaning and handling plants on turn-key basis. Due to constant process of research & development, all designs and specifications are subject to change without prior notice. Capacities mentioned are based on wheat. .

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Seed Pre-Cleaner Machine' category

|

RADIANT EQUIPMENT COMPANY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS